The History of Wm. Butler & Co. (Bristol) Ltd.

★ 1843 to 1943 ★

by

by

T. Howard Butler

In 1954 William Butler & Co

published a history of the Company.

Seventy years on, this book is now out of copyright.

It has been digitised by the Bristol Record Society.

You can view the book and download a copy from the link below.

This book was originally intended to mark the centenary of the founding of the Company, but the Second World War delayed its writing and publication by 10 years - hence despite the book's title, it actually covers the first 110 years to 1953.

Below we have picked out the highlights and featured some of the photos from the book. Overall, it is a good read, not too technical.

You can read more about the Butler family, the Company and the Tar Works (including its history after the period covered in this book) in 'The Butlers & the Coal-Tar Distillery at Crew's Hole' by Brian Vincent and Raymond Holland (ALHA Books).

All photographs and quotes on this page are taken from the 1954 book. Hi-res versions of some of the photographs have been uploaded to Wikimedia, where that is the case they can be seen via the 'Wikimedia' link.

The Book and Its Author

The book's author was Thomas Howard Butler, the grandson of William Butler, the founder of the Company. T Howard Butler (1887-1959) joined the firm in 1909. He became a director in 1917, Managing Director in 1921 and then Chairman in 1935 on the death of his uncle J B Butler, he continued as Chairman until he retired in January 1953, leaving the business in the hands of the fourth generation of the Butler family.

The book's author was Thomas Howard Butler, the grandson of William Butler, the founder of the Company. T Howard Butler (1887-1959) joined the firm in 1909. He became a director in 1917, Managing Director in 1921 and then Chairman in 1935 on the death of his uncle J B Butler, he continued as Chairman until he retired in January 1953, leaving the business in the hands of the fourth generation of the Butler family.

As mentioned in the book T Howard Butler was also Chairman of Allen Davies & Co who produced the book. Allen Davies & Co were printers and specialised in printing card & cartons, they had a large works nearby on Knapps Lane in Fishponds. Butlers' imported Turpentine and Rosin which was used to produce Rosin Size used in the paper & card industries.

We don't know how many copies of the book were produced, but we do know that a copy was presented to each employee of the Company. These copies were signed by T Howard Butler. Further copies were available for sale and some found their way to libraries.

The standard books had dark blue covers, with the 'WB&Co' logo embosed in gold. However, there were also copies produced with red covers. These were presented to Directors and family members. The name of the recipient of each of the red covered books was embossed in the bottom right-hand corner of the front cover.

The History of the Company as Described in the Book

The first three chapters in the book describe the history of the Company from 1843 to 1953 by considering three periods which cover the times when different generations of the family were in control. The chart below, taken from the book, shows the members of the family that were involved (the dates are when they joined & left the service of the Company, not those of birth & death).

First Period 1843 to 1889

The first period takes us from the setting up of the works in Crews Hole to the retirement of the founder William Butler. [Photo on Wikimedia]

The first period takes us from the setting up of the works in Crews Hole to the retirement of the founder William Butler. [Photo on Wikimedia]

"William Butler, born in 1819 at Woodhouse Eaves, Leicestershire, must have

started work early, as was customary in those days and was first employed on the

Midland Counties Railway and then with the Bristol & Exeter Railway under

the famous Railway Engineer, I. K. Brunel.

He came to Bristol in 1843 as Manager

of the new Tar Distilling Works owned by Roberts & Daines at Crews Hole,

owners also of the Iron Works situated at Silverthome Lane, then called Barton

Road, St. Philips, Bristol."

In their book, Brian Vincent and Raymond Holland record that on the birth certificate for his second child in 1841, William Butler's occupation was recorded as 'plate-layer'. William Butler would therefore have been involved in constructing the tracks. As Engineer, IK Brunel would not have employed plate-layers directly, this would have been done by contractors working for the railway company under the direction of the Engineer.

The main contractor on the Bristol & Exeter line was George Hennett and more recent research has shown that he was involved with the Works at Crews Hole, so it seems likely that William Butler was employed by George Hennett rather than Brunel; but it is true to say he was working 'under Brunel' as in the above quote.

George Hennett's responsibilities as contractor would have involved procuring and preparing the timber including treating it. So it is easy to imagine William Butler, who it can be seen from his later success must have been a first class manager, moving up through the ranks to becoming manager of the Works as it developed.

"Early in 1863 a fire broke out at the Crews Hole Works which very nearly

demolished the whole of the plant. Roberts & Daines, no doubt fearful of this

fire risk, sold their interest to William Butler who then proceeded to rebuild the

Works and to operate it jointly with the Works at Gloucester under the style of

William Butler & Company."

By 1863, William Butler had set up his own works by the Severn at Upper Parting, Gloucester. However, he took the opportunity presented by the fire to take over the Crews Hole Works and establish a single Company operating the two sites (which it continued to do right through to 1972 when the Gloucester works were closed). The book then describes how new discoveries for uses of the chemicals that could be produced from tar allowed the Company to move on from producing wood preservative into many other fields.

Read more - Crews Hole Tar Works - 1863 Fire & Early Days >>

The Butler family lived in Summerhill House opposite the 'milesone path' entrance to Troopers Hill Field from around 1866 to 1915, so very close to the Works. The book describes William Butler's involvement in the Methodist Church and Local Government in St George as well as his interest and involvement in transport.

"He was the first Chairman of The Bristol Tramways Company and indeed, held that position until his

death on October 6th, 1900. It is recorded that, in so much respect was he held

by his employees and the citizens of Bristol generally, at the time his coffin was

lowered into the grave at Avon View Cemetery, all the trams in Bristol remained

stationary for one minute."

William Butler's grave is in Avonview cemetery, overlooking the housing now on the site of the Crews Hole Works.

Second Period 1889 to 1921

"In August 1889, the Founder retired from business and left the active management in the able hands of his three sons, William, Joseph and Thomas who had

been associated with him in his enterprise for very many years"

"In August 1889, the Founder retired from business and left the active management in the able hands of his three sons, William, Joseph and Thomas who had

been associated with him in his enterprise for very many years"

Early in this period a major fire broke out at the Crews Hole works in 1897, but overall it was a period of continued expansion.

An inovation in 1899 was the erection of a new form of tar-still allowing continuous distillation.

"It was a revolutionary method,

replacing the more expensive method of using batch pot stills in which the cooling

time and heat losses were very excessive. The new plant was promptly called

"KLONDYKE" by the workpeople who imagined it to be as productive of

riches as that famous gold field."

At around this time the most significant change in the market for tar products since since the patenting of creosote occurred - the new requirement for road tar following the development of the internal combustion engine.

"In those days all roads were water-bound,

with the result that in dry weather, dust was a great nuisance and skidding in wet

weather was a dangerous hazard to anybody using the roads in a mechanical vehicle

having rubber tyres of any kind.

Many experiments took place to waterproof the roads by dressing with tar

and so started the development of road building and engineering that is called today

Tarmacadamed roads. This development entirely altered the outlook and production of Tar Distillation, as many of the basic products, i.e., Pitch and Creosote

are now used in the manufacture of Road Tar for the treatment of roads throughout

the country."

The book also tracks the changes to the structure (& name) of the Company.

"On the 9th November, 1905, the Company was registered as a Private Limited

Liability Company under the style of Wm. Butler & Co. (Bristol) Limited. The

Capital of the Company was £200,000 to take over, as a going concern, William

Butler & Co. The first Directors were -

W. H. Butler,

J. B. Butler,

T. Butler,

with the first named to be Chairman as long as he remained a Director."

The above named were three sons of William Butler and the book includes mini-biographies for them, as it does for all the directors of the Company over the 110 years that it covers.

The impact of the first World War on the Tar Distilling Industry is also described.

"any products derived from tar were of vital importance to

the war effort. Particular reference should be made to Toluene, the raw material

for the manufacture of T.N.T., the most important high explosive of the day."

"So important were these and other products that only a few employees were

allowed to join the Services, or if they did voluntarily, they were quickly returned

to the Works to carry out their civil employment."

At the end of this period the control of the Company was passed to the third generation, including the author of the book.

"In the year 1921, Thomas Butler, who had been Managing Director of the

Company for some years, retired from active business and handed over the management to his two sons, T. Howard Butler and Eric W. Butler."

Third Period 1921 to 1953

The account of this period starts with a description of the Company's expansion into the United States where, in association with Robinson Bros of West Bromwich, they jointly erected Tar Distillation Works in Chicago in 1924 and Clairton, Pennsylvania in 1926. Eric Butler went to America to help set up the Clairton Works, which were much larger than that at Crews Hole.

The account of this period starts with a description of the Company's expansion into the United States where, in association with Robinson Bros of West Bromwich, they jointly erected Tar Distillation Works in Chicago in 1924 and Clairton, Pennsylvania in 1926. Eric Butler went to America to help set up the Clairton Works, which were much larger than that at Crews Hole.

"The Works was operating within two years and had a distilling capacity of

290,000 tons per annum, and was at that time the largest individual Tar Works in

the world."

Back in the UK, Road Tar continued to be a major product and local residents remember the tar spraying tankers being driven slowly along a measured mile on Crews Hole Road to test that their speedometers were acurate so that they would give the correct rate of delivery of tar.

"The development of the use of tar for road construction became so important

at this time, that the Company decided to purchase a road stone quarry in order

to be able to control scientifically the coating of stone with refined tar.

They

acquired, in 1923, a quarry in the Mendips and formed the Mendip Mountain

Quarries Ltd. So successful was this venture that within a very few years, this

Company amalgamated with the Teign Valley Granite Co. Ltd., under the style

of Roads Reconstruction Ltd."

As the range of products produced continued to expand more space was needed, having taken over the land used by Conham Chemicals in 1904, the works were further extended into adjacent land at Crews Hole in the 1920s. But there was obviously tension between the Company and the Local Authority over land at Conham.

"Owing to the rapid development of housing in the neighbourhood of the

Crews Hole Works, the Kingswood and Warmley Councils compulsorily purchased

a very important and large piece of land belonging to the Company at Conham,

for the purpose of installing a sewage scheme.

This land, on the banks of the

River Avon, had been developed for very many years by the Company in using

it as a tip and, by so doing, they had raised the land well above flood level. The

action of these Councils restricted the rapidly developing Works and necessitated

a considerable amount of re-arrangement of the operations."

In the second World War the products of the Company were again important to the war effort. The Crews Hole site avoided direct hits during the bombing raids on Bristol, but there was extensive damage at the head office on Silverthorne Lane, which had been Butlers office and railhead since 1871. Read more about the history of the Silverthorne Lane site.

In 1935 the Company had become a Public Company, but it was in 1952 that the biggest change to the structure of the Company took place as a result of the nationalisation of the Gas Industry.

"Protracted negotiations between the Gas Boards and the Company took place

which culminated in the signing of a long-term contract on a co-operative basis,

the former taking a financial interest in the distilling side of the tar. These arrangements necessitated in 1952 the division of the interests of the Company as between

Tar Distilling on one side, and its other activities on the other. On January 1st,

1952, the Bristol & West Tar Distillers Limited was formed"

"In the following year, the Company

sold 25% of its holding in this Distilling Company to the South Western and

Wales Gas Boards."

After the period covered by the book, in 1962, the Gas Board took 100% ownership of Bristol & West Tar Distillers and the Butler Company moved all its remaining operations to the new site it had developed at Avonmouth. In 1970 ownership passed to British Steel who then ran the Works until it closed in the 1980s.

Other Activities

Chapter IV of the book covers 'other projects and activities in which the

Company has participated over its history'. These include Rosin Distillation; Naval Stores (products from the gum of pine trees) & Wood Tar; Disinfectants; Lubricating Oil Refinery and Tung Oil.

Chapter IV of the book covers 'other projects and activities in which the

Company has participated over its history'. These include Rosin Distillation; Naval Stores (products from the gum of pine trees) & Wood Tar; Disinfectants; Lubricating Oil Refinery and Tung Oil.

In addition there is 'Importation and Distribution of Petroleum'.

"After the First World War, it became imperative for the trade to find an

outlet for the large quantity of Benzole that had been produced, particularly for

war purposes.

The National Benzole Co. Ltd. was formed to distribute Benzoic

as a motor fuel, in which Wm. Butler & Co. had a substantial financial interest.

This Company established a distributing depot at St. Philips premises and opened

jointly with the National Benzoic Company an Ocean Installation at Avonmouth Docks in 1925"

This was the start of Butlers' operations at Avonmouth where they would continue after the final disposal of the Tar Distilling business. By 1953 a further depot had been aquired at Avonmouth and the depots were being used for 'the

importation and distribution of White Spirit, Kerosene, Gas Oil, Diesel Oil, etc.'

One activity that is described in this chapter that was clearly not a long-term sucess was linked to the Company's involvement in road construction.

"Iron Roads Limited

In 1932 the Company acquired the patents of F. G. Small, whose idea was

to produce a block of cast iron having a serrated surface.

Each block was an

equilateral triangle having sides of one foot in length. The block had protruding

from it three feet at the apexes on which it rested on the surface of the road which

was preferably finished with concrete. Jointing of the blocks was done by running

in hot bitumen.

The patent was good and very sound as each block was supported

on a perfect three point suspension and no rocking of it could take place. It also

had the advantage of being silent when traversed by rubber tyred vehicles, as well

as non-skid.

Several sections have been laid throughout the country, especially at busy

bus stops and a similar type of road has been used for the surfacing of the Mersey

Tunnel. The Company did not prove successful owing to the high cost of iron

and the Highway Authorities were not willing to pay the initial high price."

Transport

The next chapter covers the different forms of transport by water, rail & road used by the Company. In 1953 the Company had to move some 4,000 tons of products per week.

The next chapter covers the different forms of transport by water, rail & road used by the Company. In 1953 the Company had to move some 4,000 tons of products per week.

Water Transport

"The two Works at Crews Hole and Upper Parting, Gloucester, built by William

Butler, were sited at these points because they were alongside the Rivers Avon and

Severn respectively. Movement by water, at that time, and indeed right up to the

first World War, was the cheapest form of transport"

The development of the Company's water transport over time is then discussed, starting from canal boats hauled by donkey or pony moving on through iron barges and then steam barges, including to take pitch to the Crown Preserved Coal Co in Cardiff, a company in which Butlers also had a financial interest.

It also describes the fate of the "Ellie" the first steam tug aquired by the company.

"This boat existed for some years but came to an eventful end by being wrecked

on the "Denny," an island in the River Severn at the mouth of the River Avon.

It recalls what might have been a tragic party.

The three brothers - William,

Joseph and Thomas, together with some friends, set out one week-end to land

on the "Denny." The "Ellie" was anchored and the landing took place in

a rowing boat. The tide receded very fast and the "Ellie" dried out and fell over

on her side.

With the rising of the tide, she filled and foundered and it is interesting

to relate that so strong was the tide in the Severn that the hull of the ship was seen

at low tide somewhere near "Steep Holme," whilst the boiler was observed near

Sharpness, a distance between the two points of some 40 miles.

The "Ellie" was replaced by the steam tug " Irene " which was used up to

the time self-propelled barges were installed."

At the time the book was written Butlers' were still operating self-propelled barges including the 'Darby' and 'Jolly' built in 1903 and the 'Carbolate' which was built by Cox & Co of Falmouth in 1911. Carbolate was built to operate between Crews Hole and the Gloucester Works, via the Sharpness Canal and Gloucester Dock. Carbolate was renamed 'Ribchic Piranha' and in September 2024 was in Gloucester Docks having been converted into a floating café.

[Carbolate photo on Wikimedia]

Rail Transport

The Silverthorne Lane site at St Phillips was adjacent to the railways and acted as a railhead, products were moved between there and Crews Hole by water. The railway arches on Silverthorne Lane, many of which are now used by car repair businesses are still refered to by Network Rail as 'Butlers Arches'.

In 1953 the Company had a fleet of 81 rail tanks.

In 1953 the Company had a fleet of 81 rail tanks.

Road Transport

"In the first half of the Company's history, horses were the only means of road

transport and indeed, it was not until 1926 that the last horses of the Company

were sold.

It will be recalled that in the days of horse transport, great pride was

felt by owners in having the smartest and best horses for haulage purposes. There

was an annual competition within the City of Bristol for these horses, for which

there was great rivalry.

The parade through the streets of the City was a spectacle

much appreciated by the public and it is recorded that Wm. Butler & Co. were

the winners on several occasions"

As the 20th centuary progressed road tankers were increasingly used by Butlers', both for transporting tar and other products, but also for spraying tar directly on to the rad surface.

Directors & Employees

Directors & Employees

Chapters VI 'The Proprietors, Directors and Secretaries' & VII 'Staff and Emplyees' give information about some of those who worked for the Company but are not featured in the earlier chapters about the history of the firm.

In Chapter VI there are photographs and brief bigraphical histories of each of the Directors of the Company, including two representatives of South Western Gas Board who joined on the sale of part of Bristol & West Tar Distillers Ltd in January 1953. Some of these are members of the family, either directly or through marriage. At the end of the chapter is a list of Secretaries of the Company.

As you might expect, all the Directors are white, and with one exception, male.

The only female Director was Mrs Minie Sophia Bultler, who married Joseph Beaumont Butler (son of William Butler, the founder) in 1909. She was appointed Director on his death in 1935, but in 1940 handed the role on to her son-in-law Kenneth John Foss who had married their daughter, Margaret Beaumont Butler in 1936.

Kenneth Foss was the son of Dr Edwin Foss, who moved to Summerhill House when the Butler family moved out in around 1915. Kenneth Foss's brother Dr George Foss had also married a daughter of Joseph & Minnie Butler, Eileen.

Local people still remember Dr George Foss and his sister, Dr Joan Foss and say that at one time Dr George

was at Clouds Hill House and Dr Joan (who married another doctor, George Struthers, in

1947) was running a surgery at Summerhill House.

A Director who wasn't linked to the family, but had strong links to St George was Harold Hall.

A Director who wasn't linked to the family, but had strong links to St George was Harold Hall.

"H. Hall was born in Bristol in 1901 and after education at St. George Secondary

School, he took up a junior position with the Company in 1916. He worked

through many departments at Head Office but early showed a flair for salesmanship.

From general sales, he was made responsible for the disposal of the Company's

large production of road tar in the West of England. The sale of this product to

the Local Authorities and Quarries has been his particular activity for the last 25

years.

He was appointed to the Board of Bristol & West Tar Distillers Ltd. on

1st July, 1952."

Chapter VII names some of the longer serving staff members at both the head-office in Silverthorne Land and at Crews Hole. It also includes a number of group photographs, some of which are shown below. There is also a description of the Company's Annual Outings.

"Right from the early days, up to the first World War, it had been customary

for the Company to arrange an Annual Outing in the summer to watering places

conveniently served by rail.

A special train was chartered to take all staff and

employees from the various Works and two free tickets—one for each employee

and one for his wife or sweetheart were issued. Many happy days have been

spent in this way which have cemented the good relations between master and

man.

A few outings have taken place since, and probably the outstanding ones

were trips to the Wembley Exhibition of 1925 and the one to Blackpool in 1937

to see the Illuminations."

Pioneering and Research

Aside from the developments in the business, some of which such as continuous distillation of tar are mentioned elsewhere in the book, there are perhaps two items in this chapter that are of particular interest.

Aside from the developments in the business, some of which such as continuous distillation of tar are mentioned elsewhere in the book, there are perhaps two items in this chapter that are of particular interest.

The first relates to Butlers installation of a telephone, an extract from the Western Daily Press of Tuesday 26th August 1879 is quoted:

"THE TELEPHONE - The utility of the telephone has just received

a practical illustration by what has been effected at the business establishments of Messrs. W. Butler and Sons, tar and resin distillers of this City.

The Messrs. Butler have two places of business - one in Silverthome Lane,

St. Philips and the other Crews Hole, about two miles distant, and between

these two places communication has been established by means of the

telephone.

The instrument used is Bell's patent, all the apparatus having.

been fixed by Messrs. Butlers, who have introduced one or two important

features in connection with the working, which at once suggest themselves as improvements of considerable importance.

There is an electric

bell at each end for calling attention and by an ingenious contrivance, a

person at the St. Philips side can ring the bell at Crews Hole without

sounding the one affixed on the side at which he is engaged, thereby

obviating the confusion which is sometimes caused when the bells are

rung at both ends of the wire.

The work is a marvel of simplicity and the

whole thing has been constructed at an expense so moderate that one shilling

per week will cover the interest on the amount of the outlay. The instrument answers its purpose admirably; conversation can be carried on

between persons at both ends with the greatest possible ease, which must

be a great help in the transaction of business.

Formerly, when it was

necessary to transmit orders from St. Philips to Crews Hole, which required immediate attention, messengers had to be employed for the

purpose; whereas now, the orders can be immediately transmitted by

means of the telephone, not only effecting a considerable saving of time,

but also expense; and, considering that the cost of the whole thing was

under £100 it is not very difficult to see that the instrument will soon

pay its own cost.

This is the greatest distance to which the telephone has

been applied in this locality, but seeing the success which has attended

the venture, other business men may soon find it to their advantage to

follow the example which the Messrs. Butler have shown them."

Eight years later the Company was connected with the Central Exchange at

Bristol which had a total of only 400 subscribers.

The second field in which the Butler family notably led the way in Bristol was in motoring.

"At the advent of motoring at the end of the last century, both William Henry

Butler and Thomas Butler purchased motor cars which were some of the first in

Bristol.

It is interesting to note that on the introduction of the Motor Act which

came in force in 1904, Thomas Butler obtained the first Motor Licence and had

the first registered car in Bristol numbered AE 1.

This was a 12 H.P. 4-cylinder

Clement purchased at the Paris Motor Show and through its number soon became

the best known car in Bristol, not only to the public but to the Police - a distinction

not too desirable in view of the then restricted speed limit."

AE 1 is now the reigistration of the car used by the Lord Mayor of Bristol.

The book's concluding chapter gives a brief history of Francis F Fox & Co Ltd, Oil and Chemical Merchants, which Butlers aquired in 1937. This was to assist in the sales of their products.

Aerial Photographs

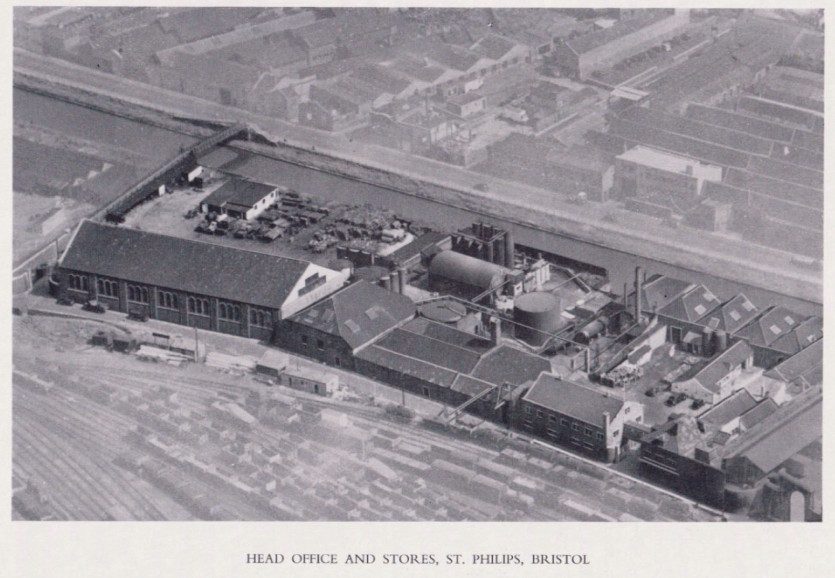

The book includes 1953 aerial photographs of the three main sites used by the Company - Silverthorne Lane, St Phillips, Crews Hole & Upper Parting, Gloucester. It is likely these were commissioned for the book.

The photos of the two Bristol sites are cropped from photos that can be found in the Britain from Above collection - links to the orginals are below the photos. The Britain from Above website also includes other photos of both sites taken at the same time, along with photos from 1926.

The photo of the Gloucester site has been uploaded to Wikimedia, Britain from Above does not include any 1953 views of that site, though there are some from 1926.

The locations of some of the buildings featured in the Butler Family Album from the 1890s can be identified from these views.

by

by

The book's author was Thomas Howard Butler, the grandson of William Butler, the founder of the Company. T Howard Butler (1887-1959) joined the firm in 1909. He became a director in 1917, Managing Director in 1921 and then Chairman in 1935 on the death of his uncle J B Butler, he continued as Chairman until he retired in January 1953, leaving the business in the hands of the fourth generation of the Butler family.

The book's author was Thomas Howard Butler, the grandson of William Butler, the founder of the Company. T Howard Butler (1887-1959) joined the firm in 1909. He became a director in 1917, Managing Director in 1921 and then Chairman in 1935 on the death of his uncle J B Butler, he continued as Chairman until he retired in January 1953, leaving the business in the hands of the fourth generation of the Butler family.

The first period takes us from the setting up of the works in Crews Hole to the retirement of the founder William Butler. [Photo on Wikimedia]

The first period takes us from the setting up of the works in Crews Hole to the retirement of the founder William Butler. [Photo on Wikimedia]

"In August 1889, the Founder retired from business and left the active management in the able hands of his three sons, William, Joseph and Thomas who had

been associated with him in his enterprise for very many years"

"In August 1889, the Founder retired from business and left the active management in the able hands of his three sons, William, Joseph and Thomas who had

been associated with him in his enterprise for very many years"

The account of this period starts with a description of the Company's expansion into the United States where, in association with Robinson Bros of West Bromwich, they jointly erected Tar Distillation Works in Chicago in 1924 and Clairton, Pennsylvania in 1926. Eric Butler went to America to help set up the Clairton Works, which were much larger than that at Crews Hole.

The account of this period starts with a description of the Company's expansion into the United States where, in association with Robinson Bros of West Bromwich, they jointly erected Tar Distillation Works in Chicago in 1924 and Clairton, Pennsylvania in 1926. Eric Butler went to America to help set up the Clairton Works, which were much larger than that at Crews Hole.

Chapter IV of the book covers 'other projects and activities in which the

Company has participated over its history'. These include Rosin Distillation; Naval Stores (products from the gum of pine trees) & Wood Tar; Disinfectants; Lubricating Oil Refinery and Tung Oil.

Chapter IV of the book covers 'other projects and activities in which the

Company has participated over its history'. These include Rosin Distillation; Naval Stores (products from the gum of pine trees) & Wood Tar; Disinfectants; Lubricating Oil Refinery and Tung Oil.

The next chapter covers the different forms of transport by water, rail & road used by the Company. In 1953 the Company had to move some 4,000 tons of products per week.

The next chapter covers the different forms of transport by water, rail & road used by the Company. In 1953 the Company had to move some 4,000 tons of products per week.

In 1953 the Company had a fleet of 81 rail tanks.

In 1953 the Company had a fleet of 81 rail tanks.

Directors & Employees

Directors & Employees A Director who wasn't linked to the family, but had strong links to St George was Harold Hall.

A Director who wasn't linked to the family, but had strong links to St George was Harold Hall.

Aside from the developments in the business, some of which such as continuous distillation of tar are mentioned elsewhere in the book, there are perhaps two items in this chapter that are of particular interest.

Aside from the developments in the business, some of which such as continuous distillation of tar are mentioned elsewhere in the book, there are perhaps two items in this chapter that are of particular interest.